Texa Konfort 780Touch Bi-Gas Air Conditioning Station

Texa Konfort 780Touch Bi-Gas Air Conditioning Station

Top of the Konfort range

It allows users to alternate services on vehicles equipped with refrigerants R134a and R123yf, as it has two tanks and two separate circuits for recovery, recycling and recharging. The service process is automated.

Other distinctive features: airtight oil bottles, scale locking/unlocking device, refrigerant weight accuracy check system, automatic cleaning device for all the hydraulic ducts.

Many connection modes

The great ease of use of the KONFORT TOUCH range and its smart approach also lie in the possibility to use the Wi-Fi connectivity for a series of activities, such as: -

- printing reports in A4 format

- receiving software and firmware updates in real time

- receiving remote technical assistance

- connecting to the myTEXA portal

- connecting with the KONFORT Mobile APP

The Bluetooth module also allows connecting the stations with several accessories, such as the A/C efficiency kit.

The stations are also equipped with a practical USB port, which can be used to back up the reports of the services performed and the entire system. It is very useful also to install software updates if the workshop does not have a Wi-Fi network.

Printing flexibility with the printers connected to the workshop’s Wi-Fi

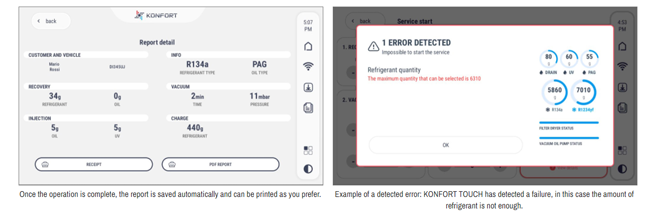

Paper reports always at hand Besides the built-in thermal printer, KONFORT TOUCH allows printing the reports of the services performed also via Wi-Fi and in A4 format, using any printer connected to the workshop’s Wi-Fi network.

KONFORT APP

Thanks to a dedicated APP, the stations communicate with Android and iOS smartphones, so that operators can follow the progress of the service and charging procedures also remotely.

The technician receives a notification in case of faults and when the service is complete. The new APP also allows you to view and manage the performed maintenance services easily, even when the station is turned off.

Android operating system everything is even easier

The KONFORT TOUCH stations are designed to be extremely well-functioning and achieve the maximum simplification of the maintenance and charging operations. To reach this goal, the Android 10 embedded operating system is used.

This choice allows better familiarity in activating the various controls, with a very intuitive visual language and an interface rich in infographics. The software updates are performed automatically and securely.

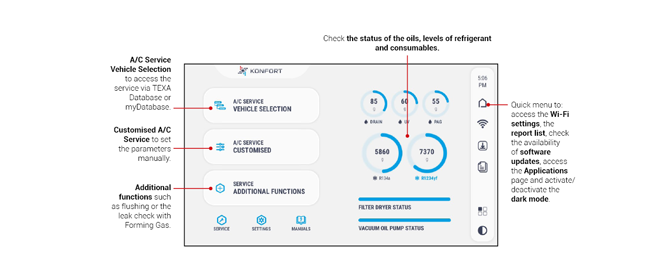

Simple and intuitive user interface starting the service is immediate

The interface is designed to provide all the necessary information in a single screen; this way, users can have direct access to the most useful operations. In next to no time, you will move from the initial station activation phases to carrying out the service.

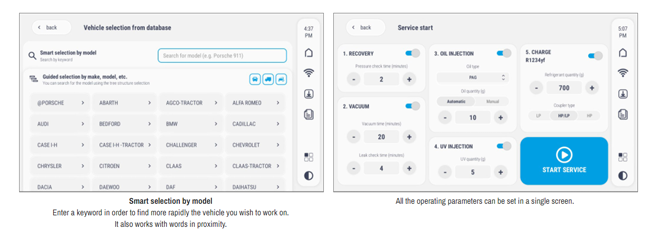

The menu, which can be browsed really easily, makes the most of the large display and minimises the “steps” required to start a charging service. Moreover, the search mode “Smart selection by model” allows you to find the vehicle you are working on by simply entering one or more keywords.

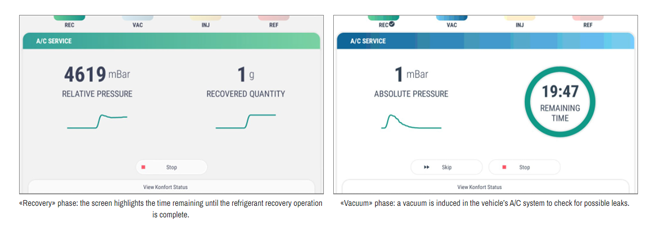

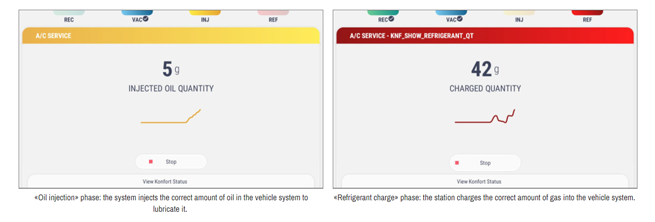

Below is an overview of the main software screens, from the service selection to the charging phases and the remote after-sales assistance request:

Online technical assistance - A specialised operator always available

The owner of a KONFORT TOUCH station can be sure not only to use a highly technological tool, but also to be able to count on constant after-sales assistance. To use this service, simply connect the station to the workshop’s Wi-Fi network, access the Applications page from the software interface and select Remote Assistance.

From here, it is possible to ask for the help of a specialised technician who will take control of the KONFORT TOUCH remotely to carry out maintenance activities in support of the operator at the workshop.

For example, the technician can activate the station, check its operating status and any errors that it may have set, calibrate the scales, check the solenoid valves, and much more.

Production and quality certified ISO TS 16949 quality system

The KONFORT TOUCH range benefits from new developments in materials, technologies and automated production procedures that resulted in TEXA gaining an ISO TS 16949 certification. All phases are subject to strict quality control, from component selection and development to machining, assembly, distribution and after-sales service.

After assembly, the stations enter the testing department where the electrical system is tested and the scales sensors and pressure transducers are calibrated. Functional testing is then performed to verify that all components and devices respond correctly and perform according to specifications.

Rigorous testing eliminates the risk of defects in the hydraulic system and ensures that all parts are effectively sealed. The final stage of testing takes place in a special sealed chamber and involves the injection of helium into the tank and the recharge circuit. Helium is used because its particularly small molecules are able to find even minute leaks.

The KONFORT charging stations conform to European CE/PED safety standards, to the American standards governing refrigerant purity (SAE J2099 for both R134a and R1234yf) and to those governing efficiency in the recovery of at least 95% of used refrigerant (SAE J2788 for R134a and SAE J2843 for R1234yf).

Features

- Dual refrigerant management R134a & R1234yf

- Fully automatic service management

- Automatic leak detection

- Refrigerant quantity measurement with electronic scales

- Air Tight Bottle oil anti-contamination system (patent pending)

- Automatic oil management with electronic scales

- Recovered oil quantity measurement with electronic scales

- Hybrid vehicle compatible

- Automatic service management (DATABASE)

- Customised service management

- FPS (Fan Protection System)

- Flushing system for refrigerant change

- Flushing system for oil change

- Printout of completed services via Wi-Fi

- Thermal printer

- 10” touchscreen display

- Compatibility with KONFORT APP

- 2 x 12 kg tanks

- Charging accuracy +/- 15 g

- High efficiency refrigerant recovery (over 95%)

- Two-stage vacuum pump

- Automatic oil bottle recognition (patent pending)

- Scales locking system

- Operating mode: DATABASE

- Operating mode: CUSTOMISED SERVICE

- Operating mode: MY DATABASE

- Multi-language software

- Automatic service hose length compensation

- Automatic maintenance alarm

- Simplified maintenance

- Automatic management of non-condensable gases

- Remote assistance

- Automatic, high-precision oil injection

- Automatic updates

Optional

- Refrigerant identifier kit

- Flushing kit

- A/C system efficiency kit

- Leak detection kit with Forming Gas